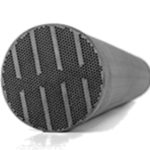

SC Filters

Theia’s SC Filters offer the filtration capability of microfiltration along with the robust nature of silicone carbide. These are not your average membranes.

The filters are fabricated from pure silicon carbide making them impervious to just about anything. They can operate in a pH range of 0-14 and temperatures up to 500 degrees and are not affected by erosive slurries or hard particulate that can tear polymeric membranes. The membranes are guaranteed for 10 years but will typically last 20. The SC filter systems can handle solids up to 5%. Because they are extruded from pure silicon carbide, there are no glued or sewn ends to give way.

When used as part of the OxyMetals system, the SC filters offer the user the ability to remove iron and arsenic without the use of any chemicals and without reliance on polymers. This step greatly simplifies the operation of the system and reduces operator attention dramatically. These unique filters can be set up in either “filter mode” where they are oriented like sand filters as a once through filter. Like sand filters, they are backwashed as needed ( using their own effluent) . SC filters can also be set up to operate like more traditional membranes where reject water is continually recirculated back to a tank and sludge is built up. either way, the solids removed from the water can be dewatered using our EZ Sludge System.

These membranes are not only tough, they outperform any other MF or UF membranes, offering 45% open pore space and 5-6 times the flux rates of other membranes. The membranes also require a lot less differential pressure to operate. The SC Filter system includes a CIP system to periodically clean the filters when used in fouling service. Since they are made from silicon carbide, we can use just about anything we want for the CIP chemical including Ozone.