Theia-Air Takes on Iron Using an Air Stripper

The Story Continues!

Air stripping is an effective and efficient groundwater technology. However the presence of iron in most groundwater formations in the northeastern US as well as many other regions in the US can make these systems difficult to operate. Fortunately there is a better solution.

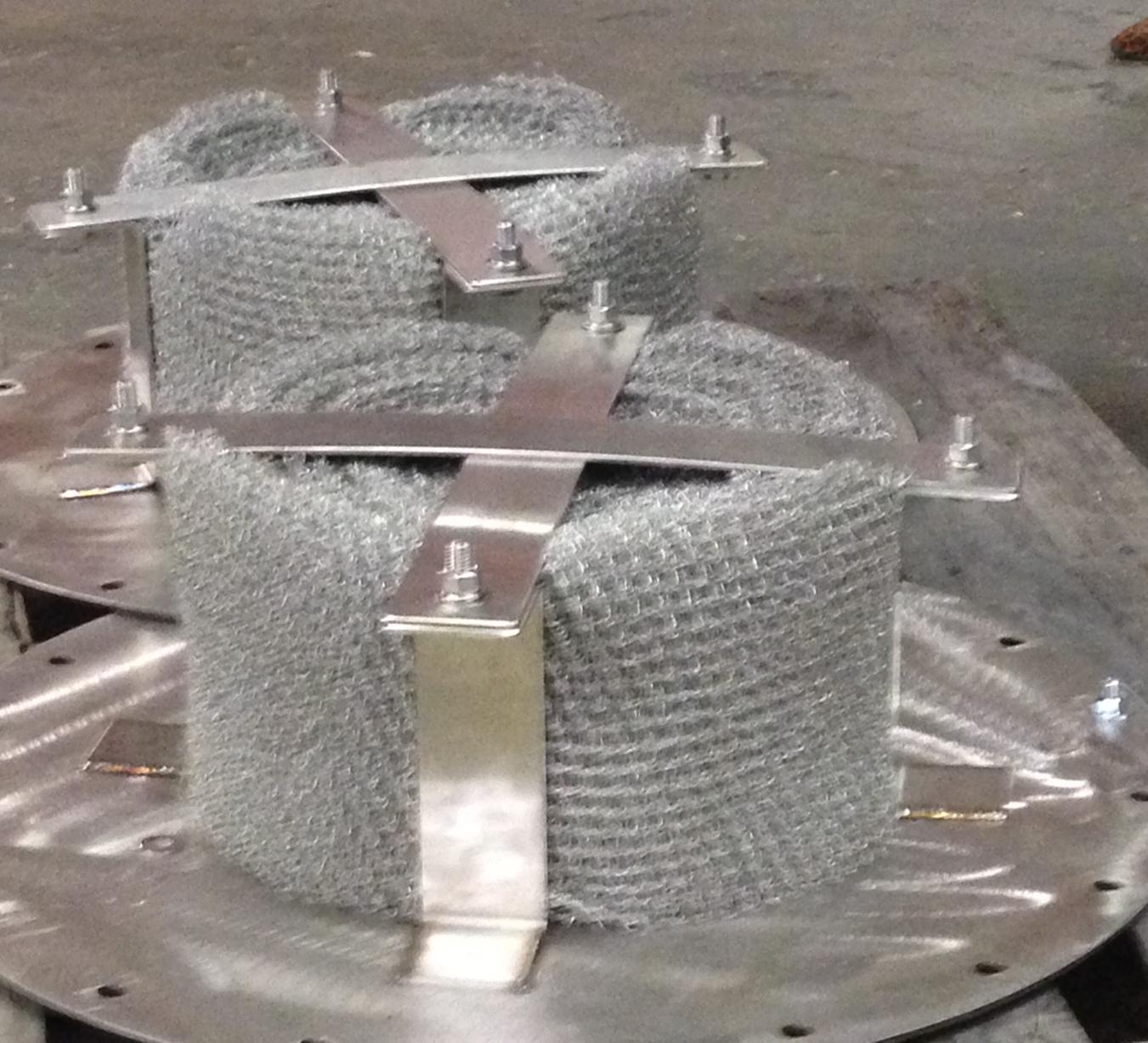

Solution: Theia delivers an effective and simple solution through the use of our innovative air stripping process that cannot clog or foul. Not only does this unique design not need any protection but it is actually part of the iron removal and metals treatment process. The system will directly oxidize any iron in the groundwater rendering it insoluble while also elevating the dissolved oxygen sufficiently to eliminate the need for a chemical oxidant when iron filters are being used. Because of the exceptionally high turbulence, additional metals treatment chemicals can be introduced if the target metals need treatment beyond oxidation.

Understandably, this all sounded a little too good to be true, and the state and the customer required a demonstration. This test had to be conducted quickly and could only last one day due to the constraints of the site and the weather. Theia quickly assembled a trailer mounted system from available equipment and brought it to the site for the demonstration.

Results: the vast majority of the VOC’s were removed as required. The system fully oxidized all the iron in the groundwater rendering is fully insoluble and had Dissolved Oxygen to spare. As can be seen from the pictures and video, the water coming in appears crystal clear but quickly turns red and then brown as it passes through the air stripper. The water in the discharge sump is not only full of oxidized iron but has a DO reading of 8.5. This design allows for the removal of very high iron loading without ANY chemicals.

After the pilot test was conducted Theia and its channel partner, Carbon Filtration Systems, received a contract to build a full scale system that included this Air Stripping System. The System utilizes the stripping system upfront to strip the majority of the contaminants as well as to oxidize the iron. The pH adjustment is also conducted in the stripping tank and a metals scavenger is able to be introduced in the high mixing zone. The stripping tank is a specially designed three-chamber cone bottom settling tank. This design allows any oxidized and settled metals to be drawn from the sludge connection. By oxidizing a large quantity of iron, we are also co-precipitating the small amount of arsenic in the groundwater.

Following the stripping system is a simple set of iron filters which utilize a catalytic media that removes iron without the use of any chemicals. The media does rely on a high level of Dissolved Oxygen which our stripping system delivers in ample quantity. The filters backwash using their own effluent and send their backwash water to a cone bottom settling. The backwash water itself is recovered and sent back to the front end of the system. Sludge accumulates over time in the settling tank and will periodically need to be removed.

The system includes a carbon polish and our metals media at the end, just in case, to remove trace any trace arsenic that is not precipitated.

The system has been installed and is currently going through the proving stage. There were a few glitches which have now been corrected and we are awaiting final sign off from the client.